PCB Box Build Assembly Services: Streamlining Complete Product Builds

Building a complete electronic product can feel like a puzzle with a lot of pieces. You’ve got the circuit boards, the cases, the wires, and all sorts of other bits and bobs. Instead of managing all of that yourself, there are services that can take your printed circuit boards and put them into a finished product, ready to go. These are called pcb box build assembly services, and they handle everything from putting the board in its case to connecting all the wires and making sure it all works. It’s a way to make the whole manufacturing process a lot simpler and faster.

Key Takeaways

- Box build assembly goes beyond just putting a circuit board into a box; it’s about integrating all the components into a fully functional product.

- Partnering for these services can speed up how quickly you get your product to market and can also lead to better quality control.

- These services simplify your supply chain by consolidating multiple assembly steps and suppliers into one point of contact.

- By bringing together various assembly stages, box build services can help reduce overall manufacturing costs.

- Many industries, from medical devices to consumer electronics, benefit from these complete product assembly solutions.

Table of Contents

Understanding PCB Box Build Assembly Services

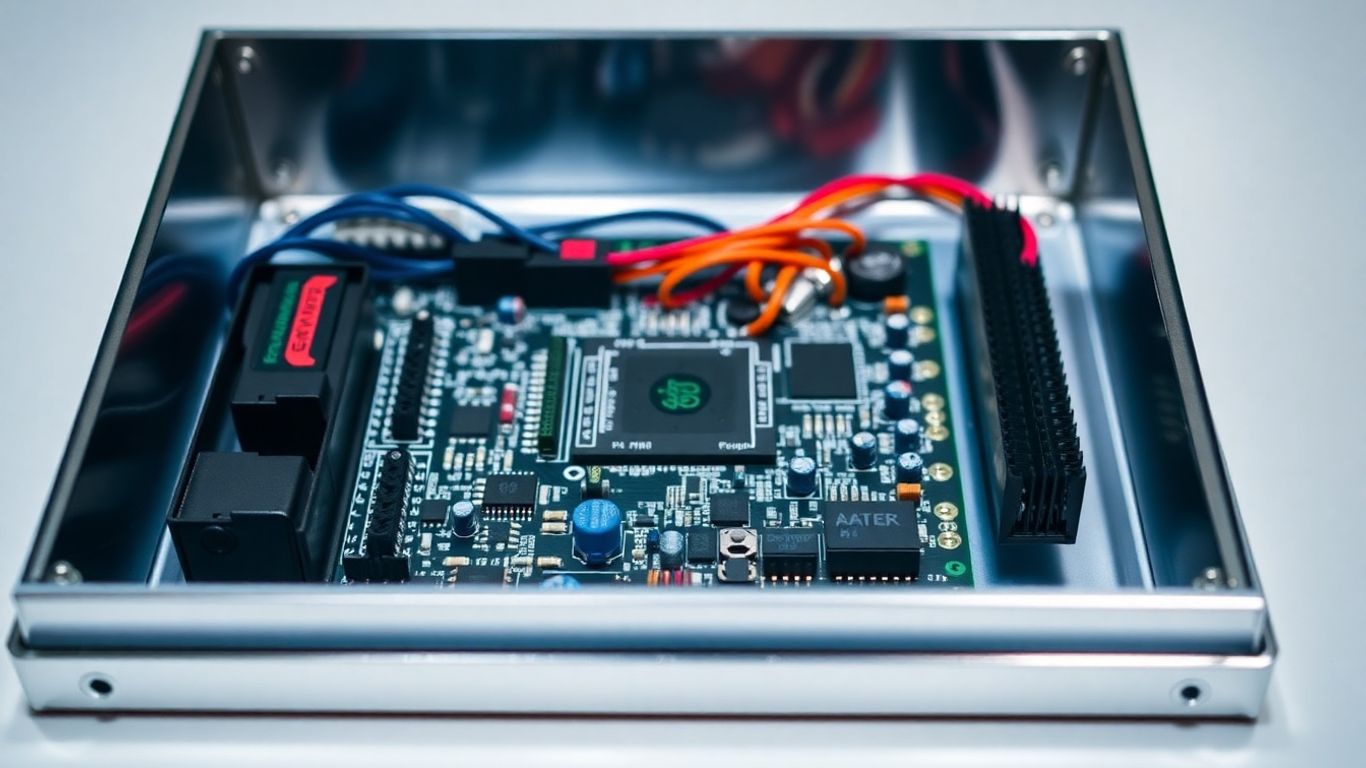

So, what exactly is PCB box build assembly? It’s basically the final step where all those individual circuit boards and their components get put into their final housing, ready to be sold. Think of it as the grand finale of putting an electronic product together. It’s more than just sticking a PCB into a plastic case; it’s about integrating everything needed to make a complete, functional system. This includes wiring, power supplies, and any other mechanical parts that make the product work as a whole. This process transforms individual electronic parts into a finished, usable item.

Defining Box Build Assembly Beyond PCB Integration

When we talk about box build assembly, we’re going way beyond just soldering components onto a circuit board. It’s the stage where the assembled PCB, which is the brain of the operation, gets integrated into its final enclosure. This involves connecting it to other parts like power sources, user interfaces, and any necessary sensors or actuators. It’s about making sure all the electronic guts play nicely with the mechanical shell and other internal bits. This is where a bare circuit board starts to look like a real product you’d find on a shelf.

The Scope of Complete System Integration

The scope here is pretty broad. A box build can be as simple as putting a single PCB into a small plastic box with a few wires and a power button. Or, it can be incredibly complex, involving multiple PCBs, intricate wiring harnesses, cooling systems, and various sub-assemblies all packed into a larger industrial cabinet. It’s all about creating a complete, ready-to-go system. This level of integration means managing a lot of different parts and making sure they all fit and work together correctly. It’s a big step up from just PCB assembly, requiring a different set of skills and a more holistic view of the product.

Key Components of a Box Build Assembly

What goes into a typical box build? Well, it really depends on the product, but you’ll usually find:

- The main Printed Circuit Board Assembly (PCBA)

- An enclosure or housing (plastic, metal, etc.)

- Power supplies and batteries

- Wiring, cables, and wire harnesses

- Connectors and switches

- Fans or other cooling components

- User interface elements like buttons, displays, or touchscreens

- Any necessary mechanical hardware for mounting and support

The goal of box build assembly is to take all these disparate parts and bring them together into a single, cohesive unit that functions as intended right out of the box. It’s the culmination of the manufacturing process, turning designs into tangible, working products.

This complete system integration is what makes box build assembly so important for getting products to market efficiently. It’s a service that consolidates many steps, simplifying the overall manufacturing journey for companies looking to produce finished goods. You can find more details on box build manufacturing and how it streamlines production.

Advantages of Partnering for Box Build Assembly

When you decide to work with a company that handles box build assembly, you’re essentially handing over a big chunk of the manufacturing puzzle. This isn’t just about getting a circuit board put into a box; it’s about getting a finished product that’s ready to go. And honestly, that can make a huge difference for your business.

Accelerated Production Cycles and Time-to-Market

Think about how long it takes to get a product from an idea to something you can actually sell. When you outsource box build assembly, you cut out a lot of the back-and-forth. Instead of managing multiple suppliers for different parts of the build – the PCB, the enclosure, the wiring, the testing – it’s all done by one team. This consolidation means fewer delays. The whole process moves faster, getting your product into customers’ hands sooner. This speed is a big deal in today’s market where being first can mean everything.

Enhanced Quality Control and Reduced Defects

It’s not just about speed, though. When one specialized team handles the entire box build, they’re focused on getting it right. They have established procedures and skilled people who know how to put everything together correctly. This focused approach means fewer mistakes slip through. You’re likely to see a drop in the number of products that have issues right out of the gate. It’s like having a dedicated quality checker for every step, from the wiring to the final screw.

Streamlined Logistics and Supply Chain Simplification

Managing a supply chain can be a real headache. You’ve got parts coming from here, there, and everywhere. Box build assembly simplifies this dramatically. Your partner handles sourcing many of the components, putting them together, and testing the final unit. This means fewer shipments to track, fewer invoices to process, and less chance of something getting lost or delayed between different stages. It really cuts down on the complexity of just getting the product made.

Significant Cost Savings Through Consolidation

When you add up all the costs associated with managing multiple suppliers, shipping components around, and dealing with potential rework due to errors, it gets expensive. By consolidating the entire box build process with one provider, you often find significant savings. You benefit from their bulk purchasing power for components, reduced labor costs because the process is efficient, and lower overhead for managing the entire operation. It’s a way to get more bang for your buck without sacrificing quality.

Comprehensive Capabilities in Box Build Assembly

When you’re looking at getting your product fully assembled, not just the circuit boards, box build assembly is where the real magic happens. It’s about taking all those individual parts – the PCBs, the wires, the casing, and anything else – and putting them together into a finished product that’s ready to go. Think of it as the final stage, where everything clicks into place.

Tailored Assembly for Diverse Product Needs

Every product is different, right? That’s why we don’t do one-size-fits-all. We work with you to figure out exactly what your product needs. Whether it’s a small, neat gadget or a larger, more complex piece of equipment with lots of moving parts, we can handle it. We’ve put together everything from simple electronic boxes to intricate systems that require careful planning and execution. Our goal is to make sure the assembly process fits your specific product like a glove.

Expertise in Enclosure Design and Fabrication

The enclosure isn’t just a box; it’s part of the product’s function and look. We can help with designing and making the right kind of casing for your electronics. This means thinking about how it will be used, what materials are best, and if any special features are needed. We handle everything from basic plastic housings to more robust metal enclosures, making sure they protect your electronics and look good too.

Advanced Wiring and Harness Assembly

Connecting everything with wires and cables can get messy fast. We specialize in creating neat, organized, and reliable wiring harnesses. This isn’t just about plugging things in; it’s about routing cables properly, making secure connections, and making sure everything is labeled correctly. Good wiring makes a big difference in how a product works and how easy it is to fix later on.

Integrated Material Management

Getting all the right parts to the assembly line on time can be a headache. We take care of that. Our material management system tracks all the components needed for your box build. This means we source the parts, manage inventory, and make sure everything is available when it’s time to assemble. This integrated approach helps prevent delays and keeps the production moving smoothly.

Managing materials effectively is key to keeping production on schedule and within budget. It involves careful planning, reliable supplier relationships, and a good system for tracking what you have and what you need.

Rigorous Testing and Quality Assurance

When you get a complete box build, you’re not just getting a circuit board shoved into a case. It’s a whole system, and making sure that system works right, every single time, is a big deal. That’s where the testing and quality checks come in. It’s not just a quick look-over; it’s a detailed process to catch problems before they ever get to you or your customers.

Proactive Error Identification in Final Assembly

Catching mistakes early saves a ton of headaches later. We look at the whole picture during the final assembly. This means checking connections, making sure wires are routed correctly, and that all the mechanical parts fit together as they should. It’s about spotting anything that looks off, even small things, before the product is sealed up.

Ensuring Product Functionality and Reliability

This is where we really put the product through its paces. We want to know it works like it’s supposed to in the real world. This involves a few different kinds of checks:

- Functional Testing: We simulate how the product will actually be used. This checks if all the buttons do what they should, if the software runs correctly, and if the outputs are what we expect. It’s like giving the product a real-world job interview.

- Environmental Testing: Depending on what the product is for, we might put it through temperature swings, humidity tests, or vibration tests. This makes sure it can handle the conditions it might face.

- Electrical Safety Checks: We perform tests to make sure there are no electrical hazards, like ensuring proper grounding and insulation. This is super important for user safety.

Automated Optical Inspection and Functional Testing

We use some pretty smart tools to help us out. Automated Optical Inspection (AOI) uses cameras to scan boards and assemblies, looking for things like misplaced components or bad solder joints that the human eye might miss. Then, there’s functional testing, which is exactly what it sounds like – we test the product’s functions. This combination of automated checks and hands-on functional validation is key to catching a wide range of potential issues. We also do things like continuity checks with a multimeter to make sure all the electrical paths are good. It’s all about making sure the product is solid before it leaves our facility. You can learn more about basic PCB board functionality testing methods to get an idea of what’s involved.

The goal of all this testing isn’t just to pass or fail. It’s about building confidence in the product. Every test is a step towards confirming that what we’ve built is reliable and will perform as expected, reducing the chances of returns or field failures. It’s a commitment to quality that you can count on.

Industries Benefiting from Box Build Solutions

Box build assembly isn’t just for one type of product; it’s a flexible solution that helps a whole bunch of different industries get their electronic devices and systems put together. Think about it – almost everything we use these days has some kind of electronics inside, and getting all those parts into a working unit can be pretty complicated.

Serving Medical Device and Consumer Electronics Sectors

In the medical field, precision and reliability are absolutely non-negotiable. A faulty device could have serious consequences. Box build assembly ensures that complex medical equipment, from diagnostic machines to patient monitoring systems, are put together with extreme care and meet all the strict regulatory standards. For consumer electronics, like smart home gadgets or personal audio devices, box builds help speed up getting new products out to people. This means faster access to the latest tech for everyone. It’s all about making sure these everyday items are built right, work as expected, and can be produced in large numbers without a hitch.

Supporting Automotive and Industrial Automation

The automotive industry relies heavily on electronics for everything from engine control to infotainment systems. Box build services are key to integrating these components into vehicles efficiently. Similarly, industrial automation, which involves robots, control panels, and complex machinery on factory floors, needs robust and dependable electronic systems. Box builds provide the structured assembly required for these demanding environments, where durability and consistent performance are paramount. It’s about making sure the machines that build our cars and run our factories are themselves built to last.

Meeting Demands of Complex Communication Systems

Communication technology is constantly evolving, and the infrastructure behind it – think network routers, servers, and telecommunication equipment – is incredibly intricate. Box build assembly plays a vital role here by integrating various circuit boards, power supplies, and interface modules into a single, functional unit. This allows for the reliable transmission of data and signals that keep our world connected. The ability to manage complex wiring and ensure all components work together harmoniously is a hallmark of good box build services in this sector.

Choosing the Right PCB Box Build Assembly Partner

So, you’ve got your PCBs all sorted, and now it’s time to get them into a finished product. That’s where box build assembly comes in, and picking the right partner for this is a pretty big deal. It’s not just about finding someone who can slap a circuit board into a box; it’s about finding a team that can handle the whole shebang, from sourcing parts to final testing. This decision can seriously impact your product’s quality, cost, and how fast you get it to market.

Evaluating Turnkey Solution Providers

When you’re looking at potential partners, see if they offer turnkey solutions. This means they handle everything from start to finish. Think about it: they source all the components, do the assembly, test the final product, and even package it up. This kind of all-in-one service simplifies things a ton. You’re not juggling multiple suppliers or worrying about who’s responsible if something goes wrong. A good turnkey provider acts like an extension of your own team, managing the complexities so you don’t have to. It’s about finding a provider that can manage everything from sourcing to shipping, reducing complexity and lead time.

Assessing Industry Knowledge and Expertise

Does the company actually know your industry? If you’re making medical devices, you need a partner who understands those strict regulations. For consumer electronics, speed and cost might be the main focus. Look for a partner with a proven track record in your specific field. Ask about their experience with OEM projects and check if they have the necessary certifications. It’s important to find a provider that has experience with OEM projects, ensuring they hold relevant certifications and comply with industry standards. They should be able to talk intelligently about your product’s challenges and suggest smart solutions.

Importance of Global Sourcing and On-Time Delivery

Getting the right parts at the right price is key, and that often means looking globally. A good box build partner will have a solid network for sourcing components from around the world. This helps keep costs down and avoids delays if one region has supply issues. But sourcing is only half the battle. On-time delivery is non-negotiable. You don’t want your product launch delayed because the assembly partner couldn’t get things done when they said they would. Ask about their supply chain management and their track record for meeting deadlines. It’s also worth checking out their facilities and capabilities, looking for modern equipment and advanced processes to meet your specific needs.

Bringing It All Together

So, when you’re looking at the whole picture of getting your electronic product made, box build assembly really does make things simpler. It takes a lot of the headaches away, from putting the circuit boards in their cases to connecting everything up and making sure it all works. By letting one company handle this final stage, you cut down on time, potential mistakes, and all the back-and-forth with different suppliers. It means your product gets finished faster and is ready to go out the door, which is pretty much what everyone wants. It’s a smart move for businesses that want to get their products out there without getting bogged down in the nitty-gritty details of assembly.

Frequently Asked Questions

What exactly is box build assembly?

Think of box build assembly as putting together the whole electronic product, not just the circuit board. It’s like building a complete toy, not just making the electronic chip inside. This includes putting the circuit board into its case, connecting all the wires, adding any other parts like buttons or screens, and making sure it all works together perfectly.

Why would I want a company to do the box build assembly for me?

It’s a great way to save time and effort. Instead of managing different companies for circuit boards, cases, and assembly, one company handles it all. This means fewer headaches for you, faster production, and often better quality because they specialize in it. It’s like hiring a caterer for a big party instead of trying to cook everything yourself.

What kind of things are included in a box build assembly?

It can include a lot of things! The main part is the circuit board, but it also involves the outer case or enclosure, all the wires and cables, power supplies, buttons, lights, screens, and sometimes even cooling fans. Basically, anything needed to make the electronic device a complete, working product.

How does box build assembly help save money?

When one company does everything, they can often buy parts in bulk for less money. Also, by having fewer steps and fewer companies involved, you cut down on shipping costs, extra labor, and the time things might get delayed. It simplifies the whole process, which usually leads to lower overall costs.

Does box build assembly mean the product will be tested?

Yes, absolutely! A big part of box build assembly is making sure the final product works correctly. Companies that offer this service will test the assembled product to check that all the parts function as they should, ensuring it’s reliable and ready for customers.

Can box build assembly be used for different types of products?

Definitely! Box build assembly is used for all sorts of things, from simple gadgets you use every day, like smart home devices, to more complex machines used in hospitals, factories, or cars. Whatever your electronic product is, if it needs to be put together in a case with other parts, box build assembly is likely a good fit.

ANZER offers complete PCB (Printed Circuit Board) box-build assembly services, integrating and assembling electronic and non-electronic components into a complete product or system enclosure. Our assembly process involves putting the PCBs and mechanical, electrical, and software components into a finalized enclosure, often called a “box” or a “chassis.” Depending on our customer’s needs, this final product can be a simple or complex electronic device, a machine, or a system.