Aerospace electronics assembly at ANZER is the process of manufacturing and assembling printed circuit boards used in aerospace applications. A printed circuit board is a crucial component in electronic devices that provides mechanical support and electrical connections between various electronic components.

In the aerospace industry, PCBs are used in a wide range of applications, from avionics systems in aircraft to guidance and control systems in spacecraft. Aerospace PCB assembly requires adherence to stringent quality standards (such as AS9100:2016 Certification, as is ANZER) and reliability due to the critical nature of these applications.

Depending on the application, the assembly process involves the following steps:

- Design and Layout: ANZER engineers design the PCB layout using specialized software, determining the arrangement of components, traces, and vias on the board. In aerospace applications, considerations include signal integrity, thermal management, and space constraints. In some cases, the customer provides the design and documentation, and ANZER follows strict procedures to produce the assembly.

- Component Procurement: High-reliability components that withstand harsh environmental conditions and temperature extremes are selected and procured. These components need to meet aerospace standards for performance and durability. The Aerospace Industries Association (AIA) is often a reference for these stringent guidelines.

- PCB Fabrication: The designed PCB layout is fabricated onto a board using specialized manufacturing processes. Multiple layers of materials, including conductive copper and insulating substrates, are used to create the PCB.

- Solder Paste Application: Solder paste is applied to the PCB’s solder pads, where components will be mounted. Solder paste is a mixture of solder alloy particles and flux that facilitates the soldering process.

- Component Placement: Surface-mount components (SMDs) and through-hole components (THCs) are placed onto the PCB using automated pick-and-place machines. Precision is crucial to ensure proper alignment and spacing.

- Soldering: The PCB is subjected to a reflow soldering process where it is heated in a controlled manner to melt the solder paste. This creates solid electrical connections between the components and the PCB. At ANZER we profile each and every printed circuit board before placing production units in the reflow oven.

- Quality Control and Testing: At ANZER, rigorous quality control processes are implemented, including visual inspections, automated optical inspections (AOIs), and functional tests to ensure the assembled PCBs meet the required specifications and reliability standards.

- Coating and Encapsulation: Depending on the application, aerospace PCBs might be coated or encapsulated with protective materials to enhance their resistance to moisture, vibration, and other environmental factors.

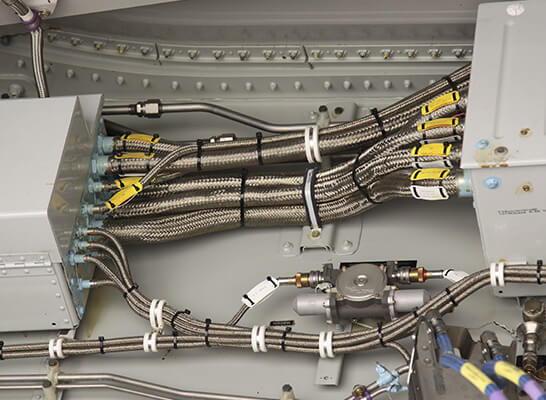

- Final Assembly: The assembled PCB may be integrated into larger electronic systems, such as avionics systems for aircraft, satellite communication systems, spacecraft control systems, or other aerospace-related equipment.

One of the critical aspects of the above procedures is additional visual and quality inspections. At ANZER continuous improvement is always a focus. Depending on the application, more is better when quality assurance is the number one priority in our aerospace assembly processes.

Aerospace Suppliers: Understanding Tier 1, Tier 2, and Tier 3

The tier aerospace supplier levels refer to the supply chain hierarchy within the aerospace industry. The aerospace industry comprises various companies and organizations that work together to design, manufacture, and support aerospace products such as aircraft, spacecraft, satellites, and related components with ANZER being a Tier 2 supplier.

The supply chain in the aerospace industry is often categorized based on the complexity and criticality of the components or services provided. Here’s a general breakdown of the tiers:

Tier 1: These are typically the original equipment manufacturers (OEMs) or prime contractors. They design and assemble the final aerospace products, such as airplanes or spacecraft. Tier 1 companies like airlines or space agencies work directly with the end customers.

Tier 2: These companies supply components, parts, or subsystems to Tier 1 companies. They play a critical role in manufacturing by integrating specialized components into the final product. Tier 2 suppliers like ANZER may work closely with Tier 1 companies to ensure their components meet the required specifications and standards.

Tier 3 and beyond: These tiers may include further suppliers that provide raw materials, specialized manufacturing processes, software solutions, or various services that support the aerospace industry.

A Tier 2 aerospace supplier is vital to the industry, providing essential components and subassemblies contributing to aerospace products’ overall performance, safety, and functionality. They often must meet rigorous quality and reliability standards to ensure the final product’s integrity. These suppliers might specialize in avionics, engines, landing gear, cabin interiors, etc.

It’s important to note that the specific roles and categorizations of companies within the aerospace supply chain can vary based on the context, the type of aerospace product being produced, and the industry standards and practices at play.

Given the critical nature of aerospace applications, the PCB assembly process for aerospace must adhere to stringent standards, including those related to safety, reliability, electromagnetic interference (EMI) mitigation, and environmental resilience to ensure the functionality and longevity of the electronic systems in aerospace vehicles.

Aerospace Electronics Blog

Ensuring Precision: The Critical Role of Aerospace PCB Assembly in Modern Aviation

You know, when we talk about planes and rockets, it’s not just about cool engines and sleek designs. There’s a whole lot of really complicated electronics packed in there, and a big part of that is the printed circuit board assembly, or PCB assembly for...

Aerospace Electronics Assembly: Delivering Precision Under AS9100 Certification

In today’s rapidly evolving aerospace industry, precision and reliability are not just advantages,they are non-negotiable requirements. Aerospace electronics assembly, a cornerstone of modern aviation and space technologies, demands unmatched accuracy, regulatory compliance, and a steadfast commitment to quality. At ANZER, an electronics design and contract...

Aerospace Electronics Manufacturing Quality Management

Quality management is of paramount importance in aerospace electronics manufacturing for several reasons: In summary, quality management in aerospace electronics manufacturing is essential for ensuring safety, compliance, customer satisfaction, and overall aerospace system reliability. It is a comprehensive approach that addresses various aspects of the...