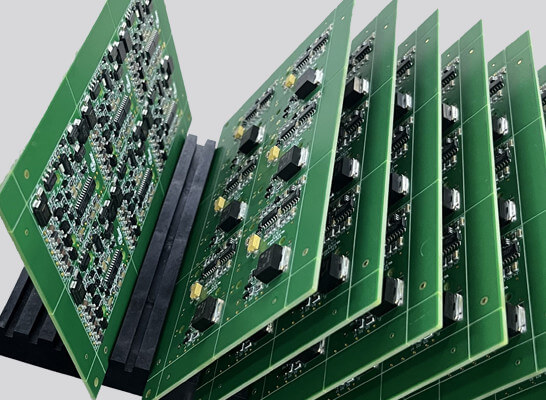

Premier PCB Assembly in Ohio

At Anzer, we provide top-notch PCB assembly services in the Ohio, USA. Our state-of-the-art facilities and experienced team ensure the highest quality and reliability for your printed circuit board assembly needs. Anzer is committed to delivering exceptional electronic assembly services that meet our client’s diverse needs. From initial design and prototyping to full-scale production, we ensure every process step is executed with the highest quality and precision.

We also specialize in aerospace electronics assembly, offering mission-critical solutions that meet the rigorous standards of the aerospace industry.

Comprehensive PCB Assembly Services Near Ohio, USA

Anzer offers a full range of electronics assembly services to meet your specific requirements:

- Surface Mount Technology (SMT) Assembly: Our advanced SMT lines precisely handle various component types and sizes.

- Through-Hole Technology (THT) Assembly: Ideal for components requiring high mechanical strength, our THT assembly ensures robust and reliable connections.

- Mixed Technology Assembly: We provide flexible solutions tailored to complex assemblies by combining SMT and THT techniques.

Types of PCB Assembly

As a provider of expert assembly services, we offer a variety of solutions to match different project needs:

- Surface Mount PCB Assembly: The efficient and accurate assembly of small, complex components on single and double-sided PCBs.

- Prototype Circuit Board Assembly: Quick and reliable prototyping services to help you bring your designs to life and test functionality before mass production.

- Full Production Runs: Scalable assembly solutions for high-volume production, ensuring consistent quality and on-time delivery.

Surface Mount PCB Assembly

Our SMT assembly capabilities include:

- High-Speed Placement: State-of-the-art machines that place components with precision and speed.

- Fine Pitch Component Handling: Expert handling of fine pitch components to ensure accurate placement and soldering.

- Automated Optical Inspection (AOI): Advanced inspection systems to verify assembly accuracy and quality.

Prototype Circuit Board Assembly

We understand the importance of prototyping in the product development process. Our PCB assembly company offers:

- Rapid Turnaround: Quick assembly times to accelerate your development cycle.

- Design Verification: Thorough testing to ensure your design meets all specifications and functions as intended.

- Flexibility: Adaptability to accommodate PCB design changes and iterations.

Fast Turn PCB Assembly

Time is critical in today’s fast-paced market, As a responsive PCB assembly company, we understand the importance of quick turnaround times. Our fast-turn PCB assembly services are designed to meet tight deadlines without compromising quality. We've covered you whether you need rapid prototyping or quick production runs.

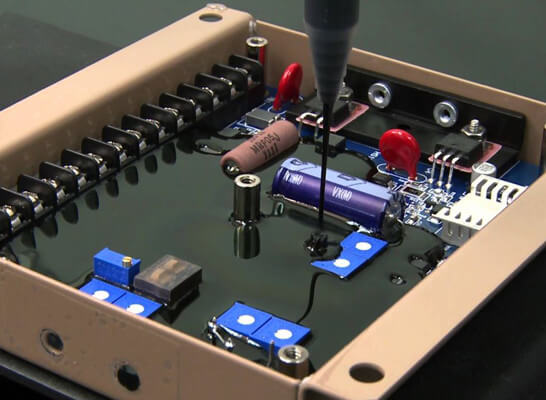

Our PCB Assembly Process

Our meticulous PCB assembly process ensures the highest quality and reliability at every stage:

- Design Review: Comprehensive review of your design files to identify and resolve potential issues.

- Component Sourcing: Reliable sourcing of high-quality components to meet your specifications.

- Assembly: Precision assembly using advanced SMT and THT techniques.

- Testing and Inspection: Rigorous testing and inspection to verify functionality and quality.

- Final Assembly and Packaging: Secure and protective packaging ensures your boards arrive in perfect condition.

Quality and Reliability

Why Choose Anzer as Your PCB Assembly Partner?

Quality is at the core of everything we do. Our printed circuit board assembly services adhere to stringent quality control standards, ensuring each product meets your specifications. We employ rigorous testing procedures to guarantee performance and durability and hold the following quality certifications:

- Expertise: With years of experience in the industry, our team brings unparalleled expertise to every project.

- State-of-the-Art Facilities: Our cutting-edge manufacturing facilities have the latest technology to handle even the most complex assemblies.

- Customer-Centric Approach: We work closely with every client to deliver precision PCB assembly services that meet exact needs.

Contact Us

Ready to start your PCB assembly project? Contact us today to learn more about our services and how we can assist you.