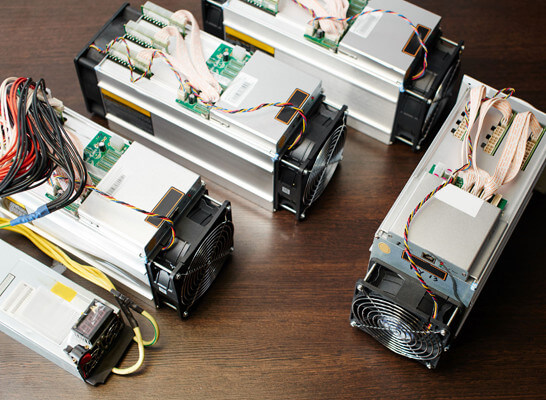

ANZER offers complete PCB (Printed Circuit Board) box-build assembly services, integrating and assembling electronic and non-electronic components into a complete product or system enclosure. Our assembly process involves putting the PCBs and mechanical, electrical, and software components into a finalized enclosure, often called a “box” or a “chassis.” Depending on our customer's needs, this final product can be a simple or complex electronic device, a machine, or a system.

Anzer’s PCB box-build assembly services include:

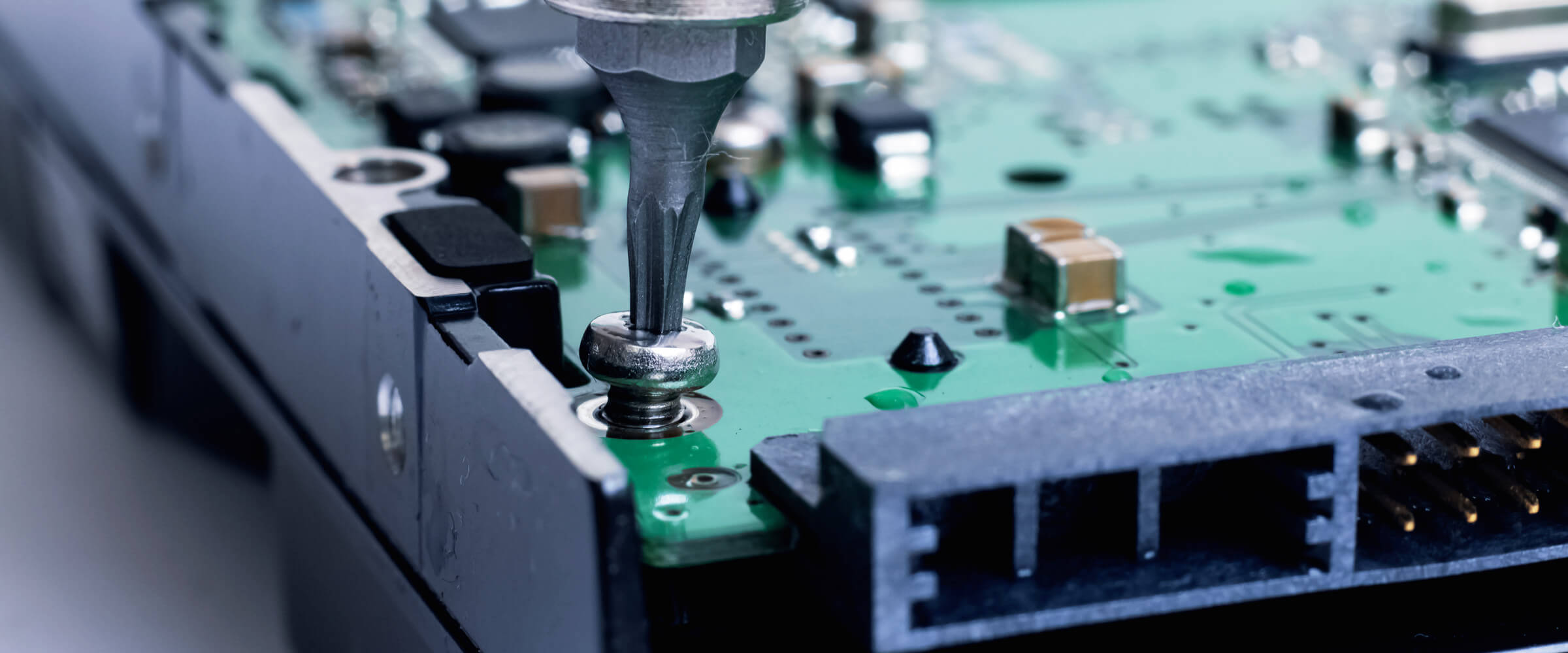

- PCB Integration: This consists of assembling the printed circuit boards, which are the backbone of the electronics, onto the enclosure or chassis. It includes soldering components on the PCB, connecting wires and cables, and ensuring proper electrical connections.

- Mechanical Integration: Besides electronics, the assembly process often includes integrating mechanical components such as brackets, connectors, hinges, displays, buttons, and other hardware that might be required for the functioning of the device.

- Cabling and Wiring: Connecting different system parts often requires intricate cabling and wiring. This involves ensuring proper cable routing, strain relief, and cable management to maintain organization and prevent interference. With over three decades of experience, ANZER understands there are no shortcuts to a quality result.

- Component Procurement: As a service provider, ANZER handles the sourcing and procuring of components required for the assembly process, including electronic components, mechanical parts, and all necessary materials. We are highly proficient in inventory acquisition and management.

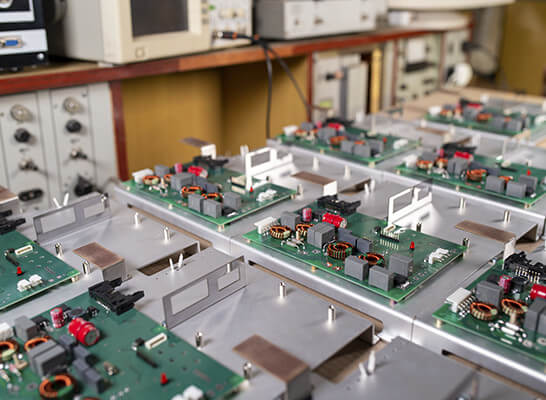

- Testing and Quality Control: Rigorous testing is crucial to ensure the final assembled product meets quality standards and functions as intended. This often involves functional testing, electrical testing, performance testing, and more.

- Enclosure and Packaging: The assembled product is frequently placed within an enclosure that provides protection, aesthetics, and sometimes environmental sealing. ANZER can design and assist such that the packaging can withstand transportation and provide user-friendly access as required.

- Documentation: Detailed documentation of the assembly process, including schematics, bills of materials, assembly instructions, and testing procedures, is managed and stored in secure electronic and paper files. We follow strict procedures to meet our certification guidelines whether a project is designed in-house or customer provided.

- Customization: Our box-build assembly services are highly customizable, catering to specific customer requirements. Depending on the project’s complexity, services may range from simple to complex system integration involving multiple subsystems. ANZER is known for flexibility when working to exceed our customer’s expectations.

- Project Management: ANZER coordinates all stages of assembly, including procurement, integration, testing, and delivery. We utilize advanced inventory and project management tools to meet timelines and quality standards. This results in quality electronic products being On-Spec. On-Time. On-Budget.

Industries often requiring PCB box-build assembly services include consumer electronics, industrial automation, medical devices, telecommunications, automotive electronics, and aerospace. By outsourcing assembly services to ANZER, your company can focus on its core competencies while relying on specialized experts to assemble and integrate its products.

Box Build Blog

PCB Assembly Factories in the USA: Why ANZER Stands Out

Behind every smart device, flight system, or medical instrument lies a small but mighty hero – the printed circuit board (PCB). PCBs are the backbone of modern electronics. And while design innovation often gets the spotlight, it’s the manufacturing quality that determines whether a product...

Full Turnkey PCB Assembly and Contract Manufacturing Explained

Every engineer has had that moment. You’ve nailed the design, finalized the layout, and your prototype works beautifully. Then comes the big question – who’s going to build it? You could try juggling component sourcing, assembly, testing, and logistics across multiple vendors… or you could...

Choosing the Right Electronic Contract Manufacturing Company

Every innovation starts with an idea – a spark on a whiteboard, a prototype on a lab bench, or a vision for something better. But between design and delivery lies the real challenge: manufacturing. That’s where an electronic contract manufacturing company (ECM) steps in. These...