Mastering Through Hole PCB Assembly: A Comprehensive Guide

Hey everyone! So, we’re diving into the world of making circuit boards, specifically the through-hole kind. You know, those older but still super reliable boards where component legs actually go through the board? Yeah, those. It might seem a bit old school with all the tiny surface-mount stuff out there, but honestly, through-hole PCB assembly still has its place, and a big one at that. It’s all about making connections that really stick, especially when things get tough. We’ll break down what it is, how it’s done, why you’d pick it, and how to make sure it’s done right. Let’s get into it!

Table of Contents

Key Takeaways

- Through hole PCB assembly means putting component legs through drilled holes in the board and soldering them. This makes a really strong connection.

- The process involves drilling holes, putting components in (by hand or machine), and then soldering them, usually with a wave solder machine for bigger jobs.

- This method is great because it makes the board super strong and can handle rough conditions, like lots of shaking or heat.

- It’s a good choice for heavy parts, things that need to last a long time, or when you might need to fix it later.

- Making sure everything is done right, following the rules like IPC standards, is important for a good, working board.

Understanding Through Hole PCB Assembly

Defining Through Hole PCB Assembly

Through-hole PCB assembly is a method for putting electronic parts onto a circuit board. It’s been around for a while and is known for making connections that are really strong and can handle a lot of physical stress. Basically, components have little wires, called leads, that you push through holes drilled in the board. Then, you solder these leads on the other side. This creates a solid mechanical link, not just an electrical one. It’s a go-to for situations where the board might get bumped around or experience temperature changes.

Key Differences: Through Hole vs. Surface Mount Technology

When you’re looking at PCB assembly, you’ll often hear about two main types: through-hole and Surface Mount Technology (SMT). They do the same basic job – connecting components to a board – but they go about it very differently. SMT is the newer kid on the block, where components are just placed and soldered onto the surface of the board. Through-hole, on the other hand, uses those drilled holes we talked about. This makes through-hole connections much stronger mechanically. SMT is great for making small, lightweight devices because you can pack more components into a smaller space. Through-hole is better when you need something that’s built to last, like in heavy-duty machinery or cars.

Here’s a quick look at how they stack up:

| Feature | Through-Hole Assembly | Surface Mount Technology (SMT) |

|---|---|---|

| Component Attachment | Leads go through drilled holes | Components sit on the surface |

| Mechanical Strength | Stronger, more robust connection | Weaker connection |

| Space Usage | Takes up more space | Ideal for compact designs |

| Best For | High-power, high-stress applications | Small, lightweight devices |

Core Principles of Through Hole Technology

The main idea behind through-hole technology is creating a secure, lasting connection. It’s not just about electricity flowing; it’s about the physical bond holding the component in place. This is achieved through a few key steps:

- Precision Drilling: Holes are drilled into the PCB that are just the right size for the component leads. This ensures a snug fit.

- Component Insertion: The leads are pushed through these holes. For some parts, this can be done by hand, especially for prototypes, but for larger production runs, machines do it.

- Soldering: Once the leads are through, they are soldered to the copper pads on the other side of the board. This solder joint is what makes the connection both electrical and mechanical.

The strength of a through-hole connection comes from the component’s leads passing through the board and being soldered on the opposite side. This creates a physical anchor that is much harder to break than a surface-mount connection, which relies solely on solder holding the component to the board’s surface.

This method is favored when the electronic device needs to withstand significant vibration, physical shock, or thermal cycling without failing. Think about equipment used in factories or devices that are constantly being plugged and unplugged; through-hole assembly is often the choice there.

The Through Hole PCB Assembly Process

Alright, let’s get into how through-hole PCB assembly actually happens. It’s not just about sticking parts on a board; there’s a definite flow to it, and each step matters if you want things to work right and last.

First things first, you need holes. These aren’t just random holes; they’re drilled with a lot of care. The size of each hole has to be just right for the leads of the component that will go through it. Think of it like fitting a peg into a hole – too big and it’s wobbly, too small and you can’t get it in without damaging something. The drill bits are usually made of carbide and spin really fast. For most standard holes, CNC machines handle this because they’re super accurate and can do it quickly, especially for big runs. But if you’re dealing with really tiny holes, like in high-density boards, sometimes lasers are used. They vaporize the material, which is pretty neat but also more expensive and slower for bigger holes.

Key Drilling Considerations:

- Hole Size Accuracy: The diameter of the hole needs to be very close to the diameter of the component lead. We’re talking tolerances of a few thousandths of an inch.

- Hole Placement: The location of these holes is determined during the PCB design phase and must be exact to ensure components fit correctly.

- Drilling Method: The choice between mechanical drilling, CNC, or laser depends on the board’s complexity, the size of the holes needed, and the production volume.

The precision in drilling is what sets up the rest of the assembly for success. If the holes aren’t right, you’ll have problems later on with components not fitting or connections not being solid.

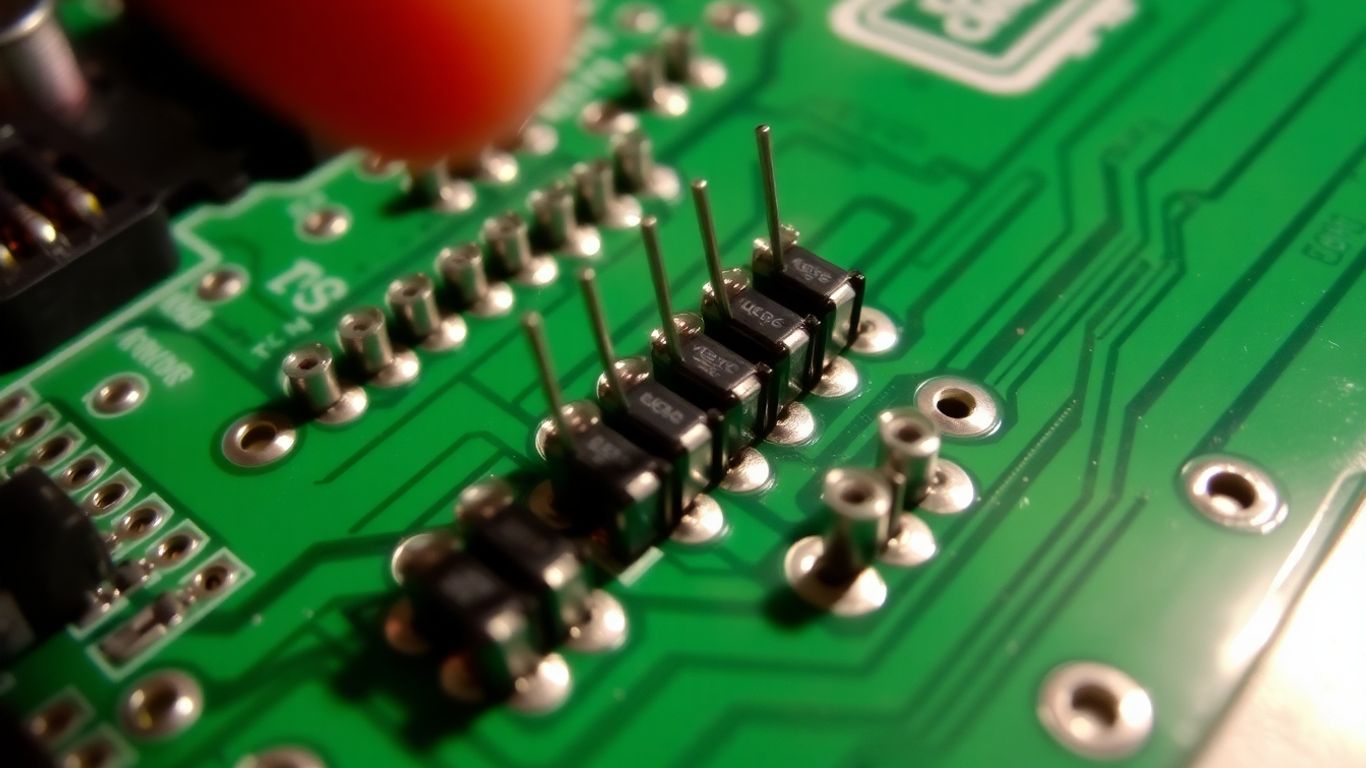

Once the holes are ready, it’s time to put the components in. For simpler boards or prototypes, this is often done by hand. Someone picks up a component – maybe a resistor, a capacitor, or a bigger part like a connector – and pushes its leads through the correct holes. It’s pretty straightforward, but it takes time, especially if you have a lot of components.

For larger production runs, automation is the way to go. Machines can pick components from reels or trays and insert them into the board much faster than a person can. These machines are programmed to know exactly where each component goes. It’s all about speed and consistency when you’re making thousands of boards.

After the components are in place, they need to be permanently attached. This is where soldering comes in. The most common method for through-hole assembly is wave soldering. In this process, the bottom of the PCB, where the component leads stick out, is passed over a continuously flowing wave of molten solder. This wave coats the leads and the copper pads, creating a strong electrical and mechanical connection. It’s efficient for boards with many through-hole parts.

However, wave soldering isn’t always perfect. Sometimes, especially with complex boards or certain component placements, you might get issues like solder bridges (where solder connects two things that shouldn’t be connected) or insufficient solder fill. For these situations, or for very small production runs, repairs, or specialized components, hand soldering is still used. A person uses a soldering iron to apply solder directly to each joint. It’s slower and requires skilled technicians, but it allows for more control and is often used to fix any problems found during inspection or to solder components that can’t go through the wave process.

Soldering Quality Standards:

- Barrel Fill: For a good connection, the solder needs to fill a certain percentage of the hole’s barrel. IPC standards often specify 50% for general use and 75% for higher reliability.

- Wetting: The solder should flow smoothly and bond well to both the component lead and the copper pad, creating a shiny, solid joint.

- Defect Avoidance: Technicians and machines aim to avoid common issues like voids (air bubbles in the solder), fractures, or cold joints (where the solder didn’t heat up enough to form a proper bond).

Advantages of Through Hole Assembly

Through-hole assembly might seem like an older technique compared to its surface-mount cousin, but it’s got some serious staying power for good reason. When you need a connection that’s built to last and can take a beating, through-hole really shines. It’s not just about sticking components on a board; it’s about making sure they stay put, no matter what.

Superior Mechanical Strength and Reliability

This is where through-hole really pulls ahead. Because the component leads go all the way through the PCB and are soldered on the other side, you get a much stronger physical bond. Think of it like a rivet versus a glued-on button – the rivet is going to hold much better under stress. This makes through-hole ideal for applications where the board might experience vibrations, shocks, or just general physical handling. It’s the go-to for anything that needs to be rock-solid.

Durability in Demanding Environments

If your electronics are going to live in a tough neighborhood – like under the hood of a car, on an airplane, or in a factory floor machine – through-hole is your friend. The robust connections can handle higher temperatures and more vibration without failing. SMT components, while great for many things, can sometimes struggle when things get really hot or shaky. Through-hole assemblies are just built tougher for these kinds of situations.

Ease of Handling for Prototyping and Repairs

Working on a new design or need to fix something? Through-hole makes life a bit simpler. Because the components are larger and easier to grab, and the leads are more accessible, it’s generally easier to manually insert them. This is a big win when you’re building prototypes and might need to swap out parts quickly to test different ideas. Plus, when it comes time for repairs, desoldering and replacing a through-hole component is often less fiddly than with SMT.

Suitability for High-Power Components

Some electronic parts just need to handle a lot of juice. Think power resistors, large inductors, or transformers. These components often have thicker leads and generate more heat. Through-hole assembly is better equipped to handle these high-power situations. The larger leads can carry more current, and the way they’re soldered provides better heat dissipation, helping to keep these power-hungry parts from overheating.

Key Applications and Industries

When you absolutely need electronics that won’t quit, through-hole assembly is often the go-to choice. It’s not just about making connections; it’s about making them tough. Think about situations where a component failing isn’t just an inconvenience, but a serious problem. That’s where through-hole really shines.

High-Stress Applications in Automotive and Aerospace

In the automotive world, PCBs are constantly dealing with vibrations, heat, and all sorts of bumps. Engine control units (ECUs) and systems that manage power need connections that can take a beating and keep working. The same goes for aerospace. Avionics, radar systems, and communication gear out in space or on a jetliner face extreme temperatures and G-forces. Through-hole components provide a mechanical strength that surface-mount parts just can’t match in these demanding scenarios. It’s about making sure that critical systems, like those in aircraft or a car’s safety features, stay operational no matter what.

Reliability in Medical and Industrial Devices

When lives are on the line, like with medical equipment, reliability is non-negotiable. Devices used for monitoring patients or performing diagnostics need to be accurate and dependable every single time. Through-hole assembly offers that level of trust. Similarly, in industrial settings, machinery and automation systems are often subjected to harsh conditions – dust, moisture, and constant operation. The robust connections from through-hole mounting help prevent failures in these heavy-duty environments. It’s about keeping the factory running or ensuring a medical device performs as it should. You can find reliable through-hole PCB assembly services from places like Foxtronics EMS.

Leveraging Through Hole for Robust Electronics

So, why pick through-hole when other methods exist? It boils down to a few key strengths:

- Superior Mechanical Bonds: The leads go through the board and are soldered on both sides, creating a very strong physical connection.

- Durability: It holds up better against shock, vibration, and temperature changes.

- Ease of Repair: For prototypes or older equipment, swapping out a through-hole component is often simpler.

- High-Power Handling: These components can often handle more power and dissipate heat better than their surface-mount counterparts.

While surface-mount technology (SMT) is great for miniaturization and high-volume production, through-hole assembly remains vital for applications where ruggedness and long-term reliability are the top priorities. It’s a technology that continues to be relevant because it solves specific, tough engineering challenges.

It’s also worth noting that for prototyping and testing, through-hole makes it easier to swap parts around. This flexibility is a big help during the early stages of product development.

Ensuring Quality in Through Hole Assembly

Alright, so you’ve got your through-hole components all set and ready to go onto the board. But just slapping them on and hoping for the best? Yeah, that’s not really how you get a product that lasts. Quality control is where the real magic happens, making sure everything is connected right and will actually work when it needs to. It’s about catching those little mistakes before they turn into big headaches down the line.

Adhering to IPC Standards for Quality Assurance

When we talk about quality in electronics, there’s a set of rules most people follow, and that’s the IPC standards. Think of them as the industry’s handshake – everyone agrees to play by the same rules. For through-hole assembly, IPC-A-610 is a big one. It lays out what a good solder joint looks like, how components should be placed, and what’s acceptable when it comes to things like solder bridges or voids. Following these guidelines isn’t just about looking good; it’s about making sure your boards are reliable, especially if they’re going into something important like a medical device or a car.

Best Practices for Component Handling and Placement

It sounds simple, but how you handle and place the components makes a difference. You don’t want to be manhandling sensitive parts or bending leads when you don’t have to. Here are a few things to keep in mind:

- Cleanliness is Key: Always work in a clean area. Dust, dirt, or even fingerprints can get into solder joints and cause problems later on. Keep your tools and your workspace tidy.

- Gentle Does It: When inserting components, make sure the leads line up with the holes. Don’t force them. If a lead doesn’t go in easily, check for obstructions or bent leads. Sometimes a slight wiggle is all it takes, but forcing it can damage the component or the PCB.

- Orientation Matters: For components like diodes, transistors, or polarized capacitors, getting them in the right way is super important. They usually have a mark or a specific pinout. Putting them in backward means they won’t work, and might even get damaged when you power up.

- Lead Trimming: After soldering, those extra bits of component leads sticking out need to be trimmed. If they’re too long, they can sometimes bend over and touch another lead or pad, causing a short circuit. A clean cut, close to the solder joint, is what you’re aiming for.

Rigorous Inspection and Testing Procedures

So, you’ve assembled the board. Now what? You don’t just ship it out. You need to check your work. This is where inspection and testing come in. It’s the final check to make sure everything is as it should be.

- Visual Inspection: This is the first line of defense. Using magnification, you look closely at every solder joint. Are they shiny and smooth? Do they look like a little volcano or a smooth fillet? Are there any solder bridges connecting two points that shouldn’t be? Are the component leads trimmed properly?

- Continuity Testing: This is done with a multimeter. You’re checking if the electrical path is complete where it should be and, just as importantly, that there are no unintended connections. For example, you’d check if a resistor is actually connected between its two leads and not shorted to a nearby trace.

- Functional Testing: This is the ultimate test. You power up the board and see if it does what it’s supposed to do. Does the circuit perform its intended function? This might involve running specific test patterns or using specialized equipment to simulate real-world conditions.

Catching issues early, whether through careful visual checks or automated testing, saves a ton of time and money. It’s way cheaper to fix a bad solder joint on the bench than to deal with a field failure.

Ultimately, a well-built through-hole assembly is a testament to careful process and diligent quality checks.

Modern Innovations in Through Hole Technology

Even though surface mount technology (SMT) gets a lot of the spotlight these days, through-hole assembly isn’t just sitting around collecting dust. It’s actually seeing some pretty neat advancements, especially in areas where its strengths really shine. Think about it: for parts that need to be super tough or handle a lot of power, through-hole is still the go-to. The real magic is happening in how we automate and refine the process, making it more efficient and precise than ever before.

Automation and Efficiency in Assembly

We’re seeing a big push to automate more of the through-hole process. Gone are the days when everything was done by hand. Now, specialized machines can insert components with incredible speed and accuracy. This isn’t just about making things faster; it’s about reducing errors and improving consistency across the board. For example, automated insertion machines can handle a wide variety of component sizes and shapes, placing them precisely into the drilled holes. Then, wave soldering machines take over, passing the boards through a bath of molten solder to create strong, reliable joints. This level of automation is key to keeping through-hole competitive, especially for high-volume production.

Optimizing Design for Manufacturability

Designers are getting smarter about how they lay out through-hole components. It’s not just about sticking them on the board; it’s about thinking ahead to how they’ll actually be assembled and tested. This means considering things like:

- Component Spacing: Making sure there’s enough room between components for automated tools to work and for manual inspection.

- Hole Size and Plating: Using the right size holes and ensuring proper plating for good solder connections, especially for high-power parts.

- Component Orientation: Placing components in a way that makes automated insertion and soldering as smooth as possible.

This focus on design for manufacturability (DFM) helps catch potential problems early, saving time and money down the line. It’s all about making the assembly process as straightforward as possible.

The trend is towards smarter integration, where through-hole components are strategically placed alongside SMT parts on the same board. This hybrid approach allows manufacturers to benefit from the mechanical strength and ease of repair of through-hole, while still enjoying the miniaturization and cost-effectiveness of SMT for other components. It’s a practical solution for complex electronic designs.

The Future Role of Through Hole in Specialized Sectors

So, where does through-hole go from here? It’s not going to disappear. Instead, it’s carving out its niche in areas where reliability and durability are absolutely paramount. We’re talking about:

- Aerospace and Defense: Where components need to withstand extreme conditions and vibrations.

- Automotive: Especially in critical systems like engine control units or safety features.

- Industrial Equipment: In harsh environments where robustness is non-negotiable.

- High-Power Applications: Like power supplies and inverters that need to handle significant electrical loads.

Through-hole technology will continue to be a vital part of electronics manufacturing for applications demanding superior mechanical integrity and long-term reliability. While SMT might dominate consumer gadgets, through-hole remains the backbone for many industrial and high-stress applications.

Wrapping It Up

So, we’ve gone through a lot about through-hole PCB assembly. It’s not the newest tech out there, but it’s still super important for a lot of projects, especially when you need things to be really strong and last a long time. Think about tough environments or heavy parts – that’s where through-hole really shines. While SMT has its place, don’t count out the old reliable. Understanding how to do it right, from picking the right components to getting the soldering just so, makes a big difference in the final product. It’s a solid method that’s here to stay for many applications.

Frequently Asked Questions

What exactly is through-hole PCB assembly?

Through-hole PCB assembly is a way to build electronic boards. Imagine a circuit board with tiny holes. We stick the metal legs of electronic parts, like resistors or chips, through these holes. Then, we use melted metal (solder) to permanently attach them, making a strong connection.

How is through-hole assembly different from surface-mount technology (SMT)?

Think of it like this: through-hole is like building with LEGOs that have pegs you push through holes. SMT is more like sticking small stickers onto a surface. Through-hole parts have legs that go through the board, making them stronger. SMT parts sit right on top of the board.

Why is through-hole assembly still used if SMT is newer?

Through-hole assembly makes really strong connections. This is super important for things that get bumped around a lot, like in cars or airplanes, or for parts that handle a lot of power. It’s also easier to fix or change parts on these boards.

What are the main steps in the through-hole assembly process?

First, we drill precise holes in the circuit board. Then, we put the electronic parts into these holes, either by hand or by machine. Finally, we use heat and melted metal (solder) to make the parts stick to the board permanently.

What kinds of products use through-hole assembly?

You’ll find through-hole assembly in tough places! It’s used for electronics in cars, airplanes, and big machines because it’s so reliable. It’s also great for medical equipment and anything that needs to last a long time without breaking.

Is through-hole assembly good for making just one or a few boards?

Yes, it can be! Because it’s easier to handle parts by hand, through-hole assembly is often good for making prototypes or small batches of boards. It’s simpler to swap out a component if you need to test or change something quickly.

At ANZER, we’ve spent over three decades building a legacy of excellence in PCB assembly, contract electronics manufacturing, and electronics services. Our commitment to quality and customer satisfaction has made us a trusted name in the industry.

What started as a mission to create top-quality electronics has grown into a passion for empowering businesses with innovative solutions. Over the years, we’ve refined our approach to be a flexible and dependable partner for PCB assembly.

Today, ANZER is recognized as a leader in the field, driven by cutting-edge technology, a spirit of innovation, and an unwavering dedication to exceeding customer expectations.