Mastering Flexible PCB Assembly: From Prototype to Production – Anzer

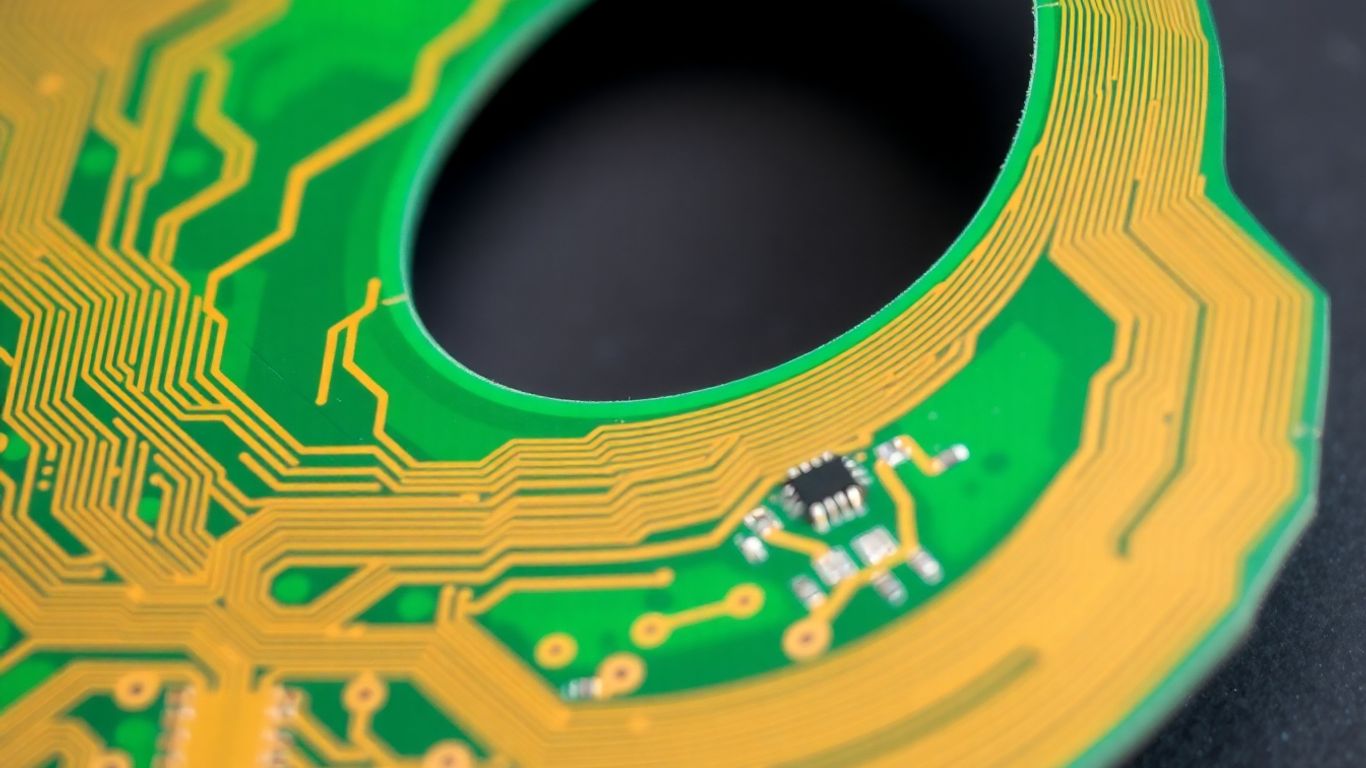

Working with flexible PCBs, or flex PCBs, can seem a bit daunting at first, especially when you’re used to rigid boards. They’ve got this bendy quality that changes how you handle them and put things together. But honestly, it’s not as complicated as it might appear. With the right approach, you can move from just a basic idea to having them made in large numbers. This guide is all about breaking down the process of Flexible PCB Assembly, from the very beginning stages to getting them ready for mass production. We’ll cover the basics, the assembly steps, and how to make sure everything turns out right.

Table of Contents

Key Takeaways

- Flexible PCB Assembly requires special attention to material properties and design considerations like bending radius to avoid damage.

- Surface Mount Technology (SMT) and automated systems are common for efficiently placing components on flex PCBs, with adhesive bonding used for complex layers.

- Handling flex PCBs during assembly needs care to prevent stress, bending, and component misalignment, while ensuring solder joints stay strong.

- The manufacturing process involves material preparation, lamination, precision etching, via creation, and final protective coatings and testing.

- Transitioning to production involves Design for Manufacturability (DFM), validating with small runs, and scaling capabilities, all while focusing on quality and cost.

Understanding Flexible PCB Assembly Fundamentals

When you’re working with flexible PCBs, it’s a bit different than just slapping components onto a standard rigid board. These boards are designed to bend and move, which means you have to think about how you’re going to build them from the get-go. It’s not just about the electronics; it’s about the physical properties of the material and how it’s going to handle being flexed, folded, or even twisted. Getting this right early on saves a lot of headaches down the line, especially when you’re trying to scale up from a few prototypes to a full production run.

Key Considerations for Flexible Substrates

The material itself is a big deal. Unlike the stiff fiberglass you’re used to, flex PCBs often use polyimide films. These films are thin and can bend, but they also have their own set of rules. You can’t just treat them like a piece of cardboard; they need careful handling. Think about how the board will be bent – is it a gentle curve or a sharp fold? This will affect everything from trace width to where you can place components. You need to design with the intended movement in mind from the very start.

Material Selection for Durability and Performance

Choosing the right material is more than just picking the cheapest option. You’ve got to consider what the final product will do. Will it be in a high-heat environment? Will it be flexed thousands of times? Different polyimide films have different temperature ratings and flex lives. Some might be better for high-frequency signals, while others offer superior chemical resistance. It’s a balancing act between cost, performance, and how long you need the board to last.

Here’s a quick look at some common material aspects:

- Polyimide (Kapton): The most common choice. It’s strong, can handle high temperatures, and is very flexible.

- Polyester (PET): Less common for high-performance flex PCBs, but can be used for simpler, lower-cost applications. It’s not as heat-resistant as polyimide.

- Adhesives: The glue that holds layers together. You need flexible adhesives that won’t crack when the board bends. The type of adhesive can impact the overall flexibility and durability.

The choice of substrate material directly influences the board’s ability to withstand repeated flexing, its thermal performance, and its overall lifespan. It’s not a one-size-fits-all decision.

The Importance of Bending Radius in Design

This is a big one. The bending radius is essentially the smallest curve the flex PCB can handle without getting damaged. If you try to bend it too sharply, you can crack the copper traces or cause the layers to separate. Designers need to specify a minimum bending radius in their plans. This isn’t just a suggestion; it’s a hard limit that the assembly process and the final product must respect.

A larger bending radius means less stress on the material, which generally leads to a more reliable product. For example, a gentle curve might have a radius of 5-10 times the material thickness, while a tighter bend might require a radius of 2-3 times the thickness, but this can significantly shorten the flex life.

Navigating Assembly Techniques for Flex PCBs

Assembling flexible PCBs is a bit different than working with their rigid cousins. Because they can bend and move, you have to be more careful during assembly to avoid damage and make sure everything works right. It’s not just about sticking components on; it’s about using the right methods to make sure the board is both functional and tough.

Leveraging Surface Mount Technology (SMT)

Surface Mount Technology, or SMT, is a common way to put small components directly onto the surface of a flex PCB. This usually involves pick-and-place machines that grab components and set them down on the flexible material. It’s a fast and efficient method, especially for making lots of boards, and it works well for tiny parts. However, you need to get the machines set up just right to avoid components being crooked, which can happen more easily on a flexible surface. We use advanced pick-and-place machines for high-volume production.

Utilizing Adhesive Bonding for Complex Layers

Sometimes, especially with multi-layer flex circuits, you need to use adhesives to hold components and layers together. This isn’t just any glue; it’s special flexible adhesive that bonds things in place while still letting the board bend. This technique is handy when SMT alone isn’t enough to get the job done. It helps keep everything secure without making the board stiff.

The Role of Automated Assembly Systems

These days, robots are doing a lot of the work in electronics manufacturing, and flex PCB assembly is no exception. Automated systems can handle everything from picking up tiny components to soldering them, all with great accuracy and speed. This means every part is placed where it should be, making it easier to produce more boards consistently. It really helps when you need to scale up production and keep the quality the same from one batch to the next.

Here’s a quick look at the main assembly methods:

- Surface Mount Technology (SMT): Components are placed directly onto the PCB surface. Great for speed and small parts.

- Adhesive Bonding: Uses special glues to secure components and layers. Useful for multi-layer designs.

- Automated Assembly: Robotic systems handle the process. Boosts efficiency and precision.

Working with flex PCBs means you need to pay attention to how the board moves. If it bends too much, parts can shift or break. It’s important to handle them carefully and design them with enough room to bend without causing problems. Making sure components stay aligned and solder joints are strong is key to a reliable flexible circuit.

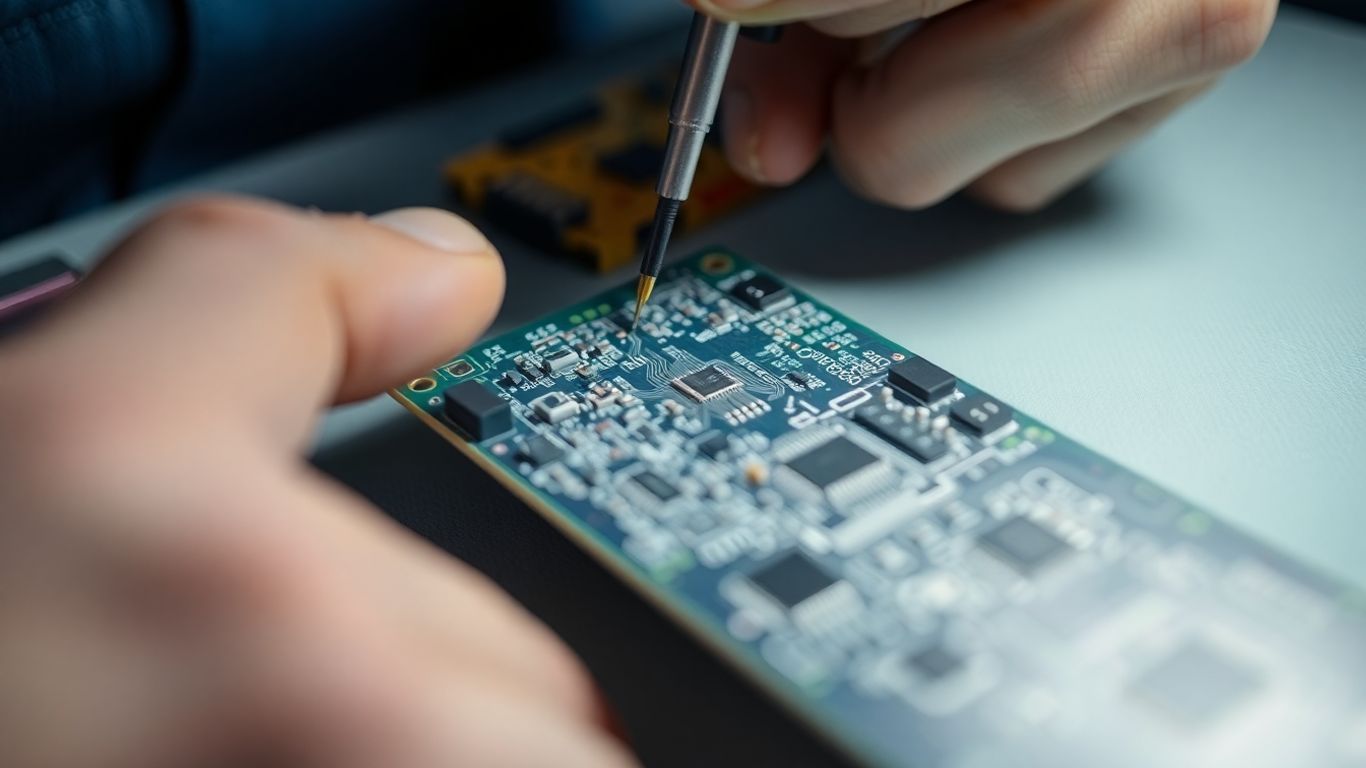

Addressing Handling and Soldering Challenges

Working with flexible PCBs is a bit different than with their rigid counterparts. Because they can bend, you have to be extra careful during assembly to avoid damaging them. It’s not just about placing parts; it’s about making sure they stay put and the connections hold up, even when the board flexes. Let’s look at some of the common issues that pop up and how to deal with them.

Mitigating Bending and Stress During Assembly

The very thing that makes flex PCBs useful – their flexibility – can also be their downfall if not handled correctly. Bending the board too sharply during assembly can lead to delamination, where layers start to separate, or even outright breakage. To keep this from happening, it’s a good idea to use specialized equipment that supports the board without putting undue pressure on it. When you’re designing your circuit, think about giving it more room to bend, a larger bending radius, to prevent damage. This is a key part of designing for manufacturability.

Ensuring Component Alignment on Flexible Surfaces

Getting components to stay exactly where they should on a flexible surface can be a real headache. As the board bends or moves, components can shift out of place, especially those tiny ones that need precise positioning. To combat this, using accurate optical alignment systems during assembly is a must. You’ll also want to double-check component placement frequently throughout the process to make sure everything is still lined up.

Maintaining Solder Joint Integrity Under Stress

Soldering on flexible boards needs a different approach than on rigid ones. Standard wave soldering just won’t cut it. You’ll typically be using hand soldering or reflow soldering methods. The trick here is to use just the right amount of solder and to avoid overheating the board. Overheating can weaken the solder joints, and since these boards are meant to move, strong solder joints are really important. A poorly soldered joint might look fine initially but could fail when the board is flexed or put under thermal stress.

Here’s a quick rundown of some common problems and how to fix them:

- Challenge: Bending and Stress

- What happens: Risk of delamination or breakage if bent too tightly.

- Solution: Use special handling tools and plan for a larger bending radius in your design.

- Challenge: Component Alignment

- What happens: Components can shift or become misaligned as the board bends.

- Solution: Employ precise optical alignment systems and verify positions often.

- Challenge: Solder Joint Integrity

- What happens: Weak joints due to improper soldering techniques or heat.

- Solution: Use hand or reflow soldering with correct heat and solder amounts.

The Step-by-Step Manufacturing Process

Making flex PCBs isn’t just a quick job; it’s a careful process with specific steps to make sure every part and connection is right. Think of it like building something intricate where each stage builds on the last to create a working and tough circuit. Here’s how it usually happens:

Material Preparation and Lamination

The whole thing starts with picking and getting the flexible base material ready. Most of the time, this is polyimide. It’s chosen because it can bend and handle heat well, which is important for the circuit to work even in tough spots. After it’s chosen, it’s cut to the size needed for the design. Then, copper foil gets bonded to both sides of this base material. This lamination step is key; it sticks the copper to the polyimide in a way that lets the board bend without breaking or losing its structure. This is where you start to see the circuit taking shape.

Precision Etching and Via Creation

Now it’s time to shape the copper into the actual circuit paths. This is done through a chemical etching process that eats away the extra copper, leaving only the lines where the electricity will flow. It’s like carving out the exact blueprint of your design. Depending on how complex the circuit is, tiny holes called vias might need to be drilled. These holes connect different layers of the circuit board. For flex PCBs, these are often very small, and they have to be placed just right so the board works correctly when it’s bent. Getting these right is super important for the board’s function.

Final Coating, Protection, and Testing

After the etching and any drilling are done, a protective layer, like a solder mask, is put on. This stops solder from going where it shouldn’t and protects the copper traces. Sometimes, a silkscreen is added too, which marks where components should go. The very last part of the manufacturing is testing. This checks if the circuit is electrically sound and works as it should. This whole process, from the base material to the final test, is designed to create a reliable flexible circuit. ANZER is your reliable partner for innovative PCB Assembly and Electronics Manufacturing Services in Ohio, USA. We help bring your designs to life through meticulous manufacturing.

The journey from raw materials to a finished flex PCB involves careful steps. Each stage, from preparing the substrate to the final electrical checks, requires precision. This methodical approach is what makes flexible circuits so versatile and dependable for various applications.

Here’s a quick look at the main stages:

- Material Preparation: Selecting and cutting the flexible substrate.

- Lamination: Bonding copper foil to the substrate.

- Etching: Creating the circuit traces by removing excess copper.

- Via Creation: Drilling holes to connect different layers.

- Coating & Testing: Applying protective layers and verifying electrical performance.

This structured approach ensures that the final product meets the demanding requirements of flexible electronics. If you’re looking for a partner to help with your PCB needs, consider looking into PCB assembly services that can handle these intricate processes.

Transitioning from Prototype to Production

So, you’ve got a working prototype of your flexible PCB, and it’s looking pretty good. That’s awesome! But now comes the big leap: getting it ready for the real world, meaning mass production. This isn’t just about making more boards; it’s a whole different ballgame. Think of it like going from baking a single cake for a friend to opening a bakery. You need to think about consistency, cost, and how to make thousands of them without losing your mind.

Design for Manufacturability (DFM) Principles

This is where you really need to look at your design with fresh eyes. What worked for one board might cause headaches when you’re trying to churn out hundreds or thousands. We’re talking about things like making sure components aren’t too close together for automated machines, or that the traces are wide enough to be reliably etched every single time. It’s about making the design easy and cheap to build consistently.

- Component Placement: Are parts too close for pick-and-place machines?

- Trace Widths & Spacing: Can these be reliably manufactured at scale? (e.g., 6-8 mil traces are common for standard boards).

- Via Sizes: Smaller vias can be more expensive to drill. Is there a more cost-effective option that still meets your needs? (e.g., minimum 0.3mm).

- Material Choice: Does the substrate hold up to the expected operating environment and assembly process?

Ensuring Quality and Reliability in Production

Getting your flexible PCBs from a few prototypes to a full production run means you need to be really dialed in on quality and making sure they work every single time. It’s not just about making them, it’s about making them right, consistently. This is where things like rigorous testing and having a solid supply chain really come into play. You can’t afford to have a batch of boards fail because of a small oversight.

Implementing Rigorous Testing and Inspection

When you’re making a lot of boards, you can’t just eyeball them. You need systems in place to catch problems early. Automated Optical Inspection (AOI) is a lifesaver here, spotting things like bad solder joints or misplaced components. For trickier issues, like internal connections or voids, X-ray inspection is the way to go. Then there’s In-Circuit Testing (ICT), which checks if everything is electrically connected correctly and functioning as it should. We aim for a defect rate below 1% per batch, which sounds strict, but it’s what keeps things reliable. Following standards like those from IPC is a good way to make sure your testing methods are up to par for flexible PCBs [3cd1].

Building a Robust Supply Chain

Your production line is only as strong as its weakest link, and often, that’s your component supply. You need to work with suppliers you can actually count on. It’s smart to keep a bit of extra stock of the really important parts, like microcontrollers or specific capacitors, just in case there’s a delay. Don’t put all your eggs in one basket; having a couple of different vendors for key parts means you’re not stuck if one of them runs into trouble. Imagine a specific capacitor you need is suddenly out of stock everywhere – having another option ready can save your production schedule.

Optimizing for Cost Efficiency Without Compromise

Making a lot of boards can get expensive, so finding ways to save money is important. Sometimes, you can switch to a simpler board design, like using fewer layers if your circuit allows, which can cut costs significantly. Buying components in larger quantities usually gets you a better price per unit, too. But here’s the thing: you absolutely cannot cut corners on quality to save a buck. Things like making sure your board can handle the heat or that your traces can carry the right amount of electricity are non-negotiable. You need to find that sweet spot where you’re saving money but not risking the performance or lifespan of your product.

The transition from a handful of prototypes to mass production requires a shift in focus. While prototypes prove a concept, production demands consistency, adherence to tight tolerances, and long-term reliability. This phase is about refining the design for repeatable, high-volume manufacturing.

Here’s a quick look at what goes into making sure your production run is solid:

- Component Selection: Using standard, readily available parts where possible.

- Process Control: Maintaining tight control over etching, plating, and lamination.

- Automated Inspection: Employing AOI and X-ray for thorough defect detection.

- Electrical Testing: Verifying impedance, continuity, and functionality.

- Documentation: Keeping detailed records for traceability and future reference.

Bringing It All Together: From Idea to Reality

So, we’ve walked through the whole process, from getting those first few flexible PCBs made to actually churning them out in big batches. It’s definitely not a simple path, and there are plenty of little things that can go wrong, especially with how delicate these flex boards can be. But by paying attention to the details, like using the right assembly methods and really thinking about how the board will be made right from the start, you can avoid a lot of headaches.

Finding a good manufacturing partner who knows their stuff is also a big help. Ultimately, getting your flexible PCB project from a simple prototype to something you can sell in large numbers is totally doable with the right planning and a bit of know-how. It’s all about making sure the quality stays high, no matter how many you need.

Frequently Asked Questions

What makes flexible PCBs different from regular ones?

Flexible PCBs, or flex PCBs, are made from bendable materials like plastic, unlike regular PCBs that are stiff. This means they can bend and fold, which is great for devices that need to be small or move a lot, like in smartwatches or foldable phones. But, because they’re flexible, they need special care during assembly to avoid damage.

What are the main ways to put parts onto a flex PCB?

There are a few main ways. Surface Mount Technology (SMT) uses machines to quickly place tiny parts right on the board’s surface. Another method is adhesive bonding, which uses special glue to stick parts down, especially for complex, layered boards. Automated assembly uses robots for super-fast and accurate work.

Why is handling flex PCBs during assembly tricky?

Flex PCBs can get damaged if bent too much or stressed during assembly. Parts can also shift around easily on the bendy surface, making them hard to line up perfectly. Getting the solder joints just right is also important, as they need to hold up even when the board bends.

Can you explain the basic steps to make a flex PCB?

It starts with preparing the flexible material, usually a plastic called polyimide. Then, it’s layered with copper. Next, a special process carves out the circuit paths, like drawing tiny wires. Tiny holes called vias are made to connect different layers. Finally, the board is protected with a coating and tested to make sure it works.

What’s important when moving from making a few flex PCBs to making many?

When you start making a lot, you need to think about ‘Design for Manufacturability’ (DFM). This means making sure the design is easy to build in large amounts. It’s also smart to make a small batch first to catch any problems. Then, you need to make sure you have enough parts and a good factory to make them all consistently.

How do you make sure the flex PCBs you make in large numbers are good quality?

Quality is key! You need to test every board thoroughly using machines that check for errors, like tiny cracks or bad connections. It’s also vital to have reliable suppliers for all the parts you need, so you don’t run out. Finding a good manufacturing partner who knows how to make many boards well is also super important.

Your Trusted Partner for Top-Quality PCB Assembly & Electronics Contract Manufacturing in Ohio

ANZER is your reliable partner for innovative PCB Assembly and Electronics Manufacturing Services in Ohio, USA. You’re developing a prototype, scaling up to mass production, or requiring specialized assembly—we’re here to deliver precision-crafted, cost-effective solutions. With latest technology and years of expertise, we guarantee products that exceed expectations every time.